Now that you've finished reading this post, what are you going to do? You should join the Forum.

Textile Notes related to fiber, yarn, fabric knowledge, spinning, weaving, processing, projects, knitting, Indian Traditional Textiles and denim manufacturing

Monday, 28 February 2011

Dyeing of Ikat Orissa Yarn with Vat and Napthol Colors

Now that you've finished reading this post, what are you going to do? You should join the Forum.

Treasure House of Information of Indian Traditional Textile Processes

Sunday, 27 February 2011

difference between Sujni and Kantha

The difference between Sujni and Kantha - Please read this document for full description

Sujni (Source of Image)

Sujni is very similar to Kantha. Because both are made of old materials and

embroider with the thread unpicked from borders of saris. But they differ in techniques:

Kantha (Source of Image)

• In Sujni, running stitch worked in straight line but in Kantha they use spiral,

circular and conical forms.

• In Sujni the outline of the motifs are done by chain stitch in dark colour but in

Kantha out lines are done by running stitch.

• In Sujni the motifs are filled with running stitch and rest of the area is also

embroidering by the running stitch with the same base colour thread but in Kantha only

motifs are filled.

Difference between Chanderi and Maheshwari Silk Saris

The Following Text is taken from this document

Difference between Chanderi and Maheshwari Silk Saris

1. In Chanderi saris the designs are created on weft while in maheshwari saris the

designs are created on warp in the beginning itself and the weft remain same.

2. While Maheshwari saris use around 4000 strings in warp, Chanderi saris use

more than 5600 strings and are therefore much more intricate and delicate.

3. Maheshwari saris normally use more linear patterns and less motifs while

Chanderi saris use a lot of motifs and they are mostly traditional floral.

4. The motifs used in Chanderi saris are more intricate than those in Maheshwari

saris.

5. Maheshwari saris use broad borders which follow patterns similar to those on

the walls of the fort of Maheshwari. Chanderi saris use a variety of designs in the

border.

Thursday, 24 February 2011

How to get the required width and weight of knitted fabric

"We have difficulties in getting the required width and weight of the knitted fabric we make. In our knitting machine we are using guage 24, 100% cotton yarn, Ne 30/1.

1) What is the weight of the unfinished fabric we should make ?

2) shall we keep the unfinished knitted fabric (100% cotton) for a certain period of time prior the dyeing or bleaching process ? If yes, then how many hours ?

3) In the calendering process: shall we change the width of the fabric which we recieve from the dyeing process ?? For example, if the width of the knitted fabric after dyeing/bleaching is 88 cm. Shall we keep the same width during the calenderig process or shall we increase it ??

4) Shall we keep the unfinished knitted fabric for a certain period of time prior we transfer it to production (cutting & sewing) ??? if yes, how many hours ??

5) When is the best time for measuring knitted fabric weight ?? Is it immediately after the knitting process and after the bleaching process ?? or shall we wait for some hours or days till the fabric take it's final shape after both processes ??? "

I welcome your comments.

Sunday, 20 February 2011

Joy of Kalamkari Handpainting

|

| http://www.thechromaacademy.com |

Saturday, 19 February 2011

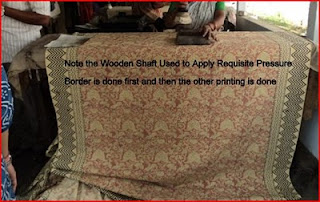

Joy of Kalamkari Printing- Process in pictures

|

| Diluted Ferrous Solution is Used to Get Teal color |

|

| Indigo or Ratanjyot is used to Get Blue Color |

|

| Alizarin Paste is Used to Get Pink Color |

|

| Flower is used to get this Gold Yellow Color |

|

| Conc. Ferrous solution is used to get this black color |

|

| Alum Gad is Boiled with Anar Chilka to Get Beige Background |

|

| Alum Gad is boiled with Alizarin to get Red background |

|

| Iron Solution Gad is boiled with Alizarin to get the black background |