Notes on Yarn for Rope Dyeing

* Yarn faces stress and stretch at ball warping, rope dyeing, rebeaming, sizing and loom shed so elongation of yarn should be more than stretch at (ball warping + Robe Dyeing+ Rebeaming + Sizing )= (2-3%) + Loom shed (about 5%)

* Tension at Ball warping should be less by 7-8% of single yarn strength.

* Strength CV should be within limits as it may give rise to weak points

* The tendency of yarn to migrate at rope dyeing can be countered by less micronaire of yarn ( should be around 3.8-4.2)

* More dropping of short fibers at long chain beaming is good

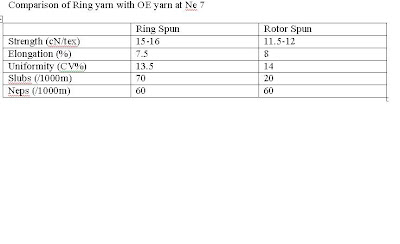

*The sensitivity settings for neps is set at +280 for rotor spun yarn and not +200 as in case of ring spun yarn. The reason for this is that the structure of rotor spun yarn is intrinsically different from that of conventional ring spun yarn. Neps in rotor yarn tend to be spun into the solid yarn body rather than remaining on the yarn surface, which is typical of ring spun yarns. Although embedded in the yarn core, these neps still represent a short mass defect and will therefore trigger the imperfection counter upon exceeding the preset value. However, compared to neps that are attached to the yarn surface, fully embedded neps are barely perceptible for the human eye. Thus, in order to balance the typical visual appearance of rotor spun yarn with the imperfection counts, +280 sensitivity setting is a common convention for rotor spun yarns.