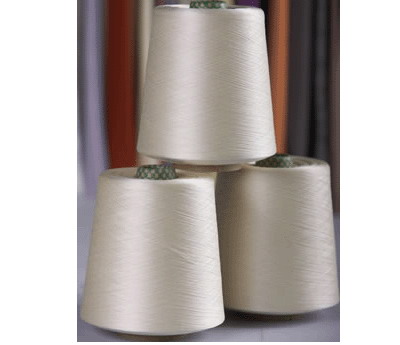

What is Raw Silk as termed commonly

When we talk about raw silk, we generally are talking about mulberry raw silk. It is the compact untwisted and undegummed silk thread that is formed by combining the required number of silk filaments drawn from as many separate cocoons by a special technique called Reeling.

What is Filature Silk

The building in which cocoons are reeled for the production of raw silk is called a filature.It is carried with

sophisticated automatic machines,to ensure production of raw silk of desired qualities. The filature concept is

seen in developed countries where the raw material (cocoons) are of superior quality.

What is the type of Silk used in Indian Villages

However, more than 50 per cent of silk is reeled by a villager using country charka which forms the cottage industry. In the group of natural fibres.

What is the percentage of Silk production of all Textile fibers in the world

Which comprises cotton, wool and silk, production of silk amounts for 0.3 per cent only.

What are the other uses of silk apart from garments and home furnishings

Silk yarn is used as A package material in pencil industry and for making talcum powder puffs. Silk is used as raw material for preparing sound-free gears for making precision machinery. In France 22-24 denier silk is used in tyre manufacturing to have a longer life span than rubber tyres. Parachutes are made from 13-15 denier silk fiber. The silk gut used in surgery for internal suturing is made from silk glands. The silk glands are dissected out and put in warm water and pulled at two ends to yield a fibre of uniform thickness. This protein is auto absorbable and need not be removed after wound healing. Silk grafts have been used successfully to replace cut arteries.

What type of production is more in India- Raw silk or Cotton waste

India is very poor producer of raw silk to meet international standards. In India raw silk production is overtaken by silk waste. India produces annually about 180 tonnes of spun silk yarn and 130 tonnes of noil yarn besides hand spun yarn.

Why Silk Reeling using Charkha is inferior

Silk reeling, using country charka is of low quality but it contributes more to the raw silk produce. The reasons

for low quality silk in country charka are as follows;

1. No sorting of cocoons. Defective cocoons are also reeled.

2. No cocoon mixing

3. Improper deflossing.

4. As there is no jettebout the dirt, gum spots etc., can be eliminated. However, the charka has Tharpatti but

cannot function like button or jettebout.

What are cocoons, what are they made up of

Cocoons

Cocoon is nothing but a protective shell made up of a continuos long protein silk filament spun by mature silkworm

Content Percentage

Fibroin 72.0-81.0

Sericin 19.0-28.0

Fat & Wax 0.5-1.0

Colouring matter & ash 1.0-1.4

What are important physical and commercial characteristics on which the production and quality of silk depends

Color

Indian races produce either white or yellow cocoons and white cocoons have a slight edge over the yellow cocoons in market price.

Shape

For easy relling spherical, oval and moderately constricted or printed cocoons are selected.

Size

The size is generally indicated by the number of cocoons per litre.Generally the number of cocoons per litre varies between 110 to 400. Uniform sized cocoons are required for reeling.

Hardness or Compactness

When a cocoon is lightly pressed between the fingers, it should not yield but should feel firm, compact and

elastic.

Grain or Wrinkle

After deflossing the cocoon surface should be granual or wrinkled with convolution.For better reeling fine granular cocoons are selected.

Weight of Cocoon

Weight of Cocoon Shell

Larger the weight of the shell, greater the silk yield.In Indian multivoltine hybrids the shell weights is 200 to

300 mg. , while it is 180 to 250 mg in multivoltine pure races. Indian univoltine cocoons have 200 and 300 mg of silk shell.

Commercial Chracteristics

1. Shell Ratio: It indicates the quality of raw silk that can be reeled from fresh cocoons. Shell ratio is the

weight of cocoon shell and weight of whole cocoon. . It varies from 12 to 19 per cent.

2. Length of filament

It denotes the length of silk in the cocoon. It varies from 300m to 1200 m.However non breakable filament length (NBFL) which is the average length of filament that can be unwound without breaks is very important.

3. Weight of reelable filament

The complete silk filament of the cocoon cannot be reeled. The outermost floss layer and innermost pelade layer cannot be reeled and therefore removed.

4. Denier

It determines the size of silk. The denier is high in outer floss layer than the middle or inner layer.The tolerance limits for the commercial raw silk are 13/15, 20/22 denier. Denier = ( Total weight of reeled silk in grams/Total length of reeled silk in meter) x 1000.

5. Raw Silk Percentage

This is the percentage of the quantity of raw silk reeled in relation to the quantity of fresh cocoons used for

reeling. This can vary from 40 to 85 per cent. Raw silk Weight = ( Wt of Reeled silk/wt of cocoon)x 100

6. Floss

It is the value outermost loose, fragmented unevenly thick silk layer of the cocoon. It is a waste silk.

7. Renditta

It is the value derived from liter of cocoons required to produce one unit (1 kg) of raw silk. It varies from 6 to

14. The lower the value, the better is the quality of Silk.

What are the various steps of Silk Manufacturing after the cocoon is ready and collected

The various steps are as follows

1. Cocoon Stifling and Conditioning

The process of killing the pupa and keeping the cocoon in good condition by storing in a proper conditions is

called stifling and conditioning of cocoons.

a. Stifling of Cocoons

It can be done by

- Sun Drying

- Steam Stifling

- Hot Air Drying

Sun Drying

It is a method of killing and drying the pupae by prolonged exposure of freshly harvested cocoons to hot sun. It is simple and cheap and drying is even/uniform. However, it is not suitable for modern reeling, can only be done on bright days, prolonged exposure can cause poor quality silk, increases wastages of silk reeling, involve space and labour and the cocoons can get dust and dirt in the process. Tussar in India uses sun drying method.

Steam Stifling

In this process, the fresh cocoons are exposed to hot wet steam, for a required period. Large quantity of cocoons can be stifled in a short time. However, it kills the pupa inside and doesnt dry it properly. There is also a problem of mould formation and leaking of body fluids of pupa onto silk. It also affect the sericin, increasing silk waste.

Hot Air Drying

In this the pupae are killed by exposure to hot air. It is the best method of stifling, giving good quality of silk

and dried pupae.

2. Cocoon Storage

After complete drying, the cocoons are to be stored in a store house which is protected from rats and is moisture proof.To protect the cocoons from fungal attack, the inside temperature and relative humidity of the store need to be maintained at 27 deg C to 30 deg C with 60-70 per cent relative humidity.

3. Cocoon Sorting

Sorting of Cocoon is done before reeling to give good quality cocoons.

4. Deflossing

Generally deflossing is done by fingers but now simple hand operated machines are also available.

5. Riddling

It is a process that separates the cocoons according to their sizes.

6. Cocoon Cooking and Brushing.

Silk thread spun by silkworms is technically called as ‘bave’. This is a composite structure which inturn has two filaments inside which are known as ‘brins’. Brins are the filaments which are produced by the two silk glands. Brins are made up of silk protein biborin synthesized in the silkglands. The brins are intrun bound by silk protein called sericin.

The cooking process is done for softening the sericin to facilitate easy unwinding of the silk filament at the same time.The sericin content of the silk filament ranges from 25 to 30 per cent, which varies in different races. In cooking process 7 to 8 per cent of sericin is dissolved.

In order to cook the cocoons properly there are different types of systems of cooking.

1. Top reeling or floating system

2. Sunken system

In top reeling the cocoon shell becomes wet and impervious to water and float in water when the cooked cocoons are put in to the reeling basin. In sunken system the shell is cooked and the process fills the cocoon with water (97- 98 per cent) and makes the cocoon heavy and which sink in the reeling water. The top reeling is a old method while sunken reeling is a latest method.

Traditionally tassar cocoons are cooked in an earthen pot at or near boiling sodium carbonate (washer man’s soda) solution for 4-6 hours. Cocoons are then reeled in semi moist condition on Natwa/Thigh, where the productivity per day per reeler comes to about 60-80 g of 60 D silk yarn.

Brushing

The cocoons have to be brushed to remove the surface floss before reeling. Floss is a lossely knit, broken, uneven thickness, water silk. Without removing the floss layer one cannot reel the proper silk. This waste layer obstructs the reeling process unless it is clearly removed. The process of removing floss layer is called “brushing”.Brushing can be done with the help of a stick, a brush or through mechanical means.

---to be continued---

Thanks for your attention. Did you find the information you were looking for ? Please leave a comment. Do you need to know more ? Please suggest a topic in the comments. You can also join the

Forum for your specific queries.