The Rapid dyes are stabilized azoic dyestuffs. These are also called as Napthol dyes

They are applied to the fibers in one operation.

Bright full colors are obtained with very good fastness properties.

Printing and dyeing with Rapid fast dyes is getting very popular specially in the traditional garments such as sarees.

Rapid fast dyes is a class of Azoic dyes. These dyes contain an insoluble azo group. These dyes are not found in the readymade form. The dye is produced by a reaction between two components. These components are:

1. Coupling compound ( Napthol)

2. Di-azo compound or di-azo salt.

They have excellent wash fastness and light fastness properties, provided these are produced properly.

How the reaction Takes place

1. Naptholisation: Napthols are insoluble in water and they are converted into water soluble compound by treating with alkali. The material is treated with this solution.

It is important to remove excess napthol from material for improving rubbing fastness. This is done with the help of centrifuging, squeezing or vacuus extraction.

2. Diazotisation: A base containing amino group (-NH2) ( which is the dye stuff), reacts with Sodium nitrite to form a solution of diazonium salt by reacting with HCL of H2SO4 in presence of 0 to 50 deg C temperature. Ice is used sometimes for the low temperature, hence they are also called Ice-colors.

3. Coupling: The treated material from the first step is then put in a bath containing diazonium solution to carry out the coupling. Thus the color is produced inside the fabric. The pH is very important here.

The material then is agitated with first water and then boiling water to remove un-reacted color and to enlarge the size of color molecules inside the fiber.

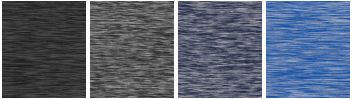

These are used for producing bright shades of color such as orange, red, scarlet, navy and black.

These are also used for printing backgrounds so that the foreground becomes prominent. Hence these are suitable where large areas of ground need to be colored. Rapid dyes are mixed with water and boiled with caustic soda and a gum paste. A receipe for rapid dyes is given here.

Certain azo dyes are known to release some aromatic amines which are considered to be carcinogenic. A lot of countries have put ban on these dyes, as discharge of the untreated dyes lead to the toxic pollution of the atmosphere and water.

Watch this video on how to dye with Azoic dyes in Laboratory